EPISODE 01

Innovating Factory

A Place Where a Robot Factory Manager Works

June 20th, 2016

To celebrate 15th anniversary of Good Smile Company, a robot factory manager started working in Rakutsuki Factory in Kurayoshi-city, Tottori prefecture. We are sure that our core fans might know about this already, but we would like to introduce what the place is like with the new robot factory manager.

Rakutsuki Factory, which is often called as Lucky Factory, is Good Smile Company’s first factory within Japan that has been built in Kurayoshi-City, on December 2014. The completion ceremony was aired live on Niconico (A famous live video streaming service in Japan), featuring the Governor of Tottori Prefecture, Hirai Shinji, the Mayor of Kurayoshi-City, Ishida Kotaro, voice actress Shimoda Asami, and the host of the event Shiraishi Minoru, making the ceremony a hot topic.

「グッスマ 国内フィギュア工場 竣工記念放送」にてタイムシフト試聴が可能。

「グッスマ 国内フィギュア工場 竣工記念放送」にてタイムシフト試聴が可能。

http://blog.nicovideo.jp/niconews/ni050092.html

Unlike toys that have simple shaping and assembling process, figures have much more sophisticated manufacturing process, and extra cost is spent on the development of molding machines and the painting tools. Despite having a factory in China, Good Smile Company decided to build one in Japan as well to increase productivity and to contribute to the local job market.

Let’s take a look on how the figures are made, by taking a tour inside the Rakutsuki Factory.

!=

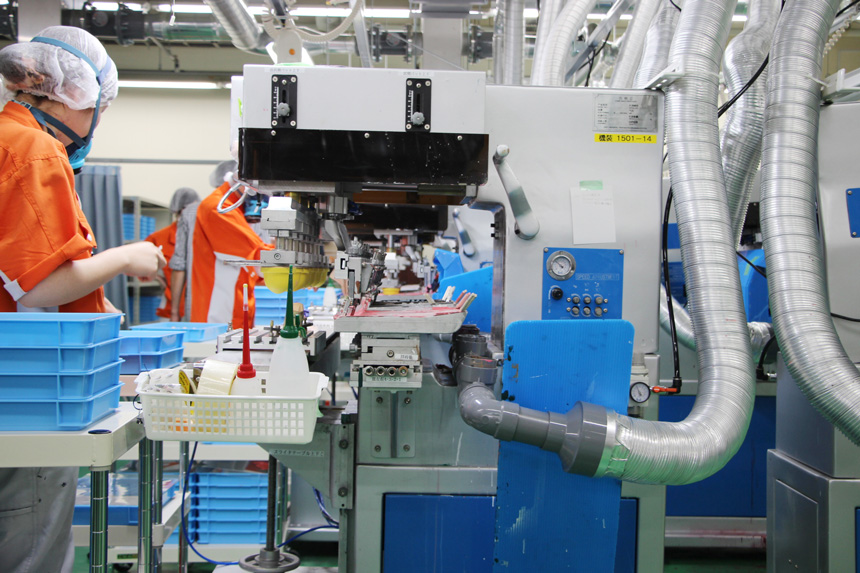

This is where the different shapes of the figures are made, by pouring plastic into the molding machine. When the parts are removed, they become the elements that make up a figure.

After the parts are removed from the molding machine, the very first step is to process the surface. Since the parts have rough surface after being molded, fluffs need to be scraped so they become smoother.

Next step is washing. By washing off not only the dusts but also oils stuck on the surface during the molding process, it is possible to upgrade the quality of painting. Just like preparation for cooking, invisible parts are the most important ones. The key factor on making quality products is doing things thoroughly.

The process that comes after is airbrush painting. This process is mostly done by human hands, and the delicate airbrush gradations are completed within this process.

We make sure that all products maintain excellent quality by training the employees, some of which are sometimes first-timers using airbrushes.

After the airbrush painting process, comes hand painting. Here we make some retouches, and work on small details.

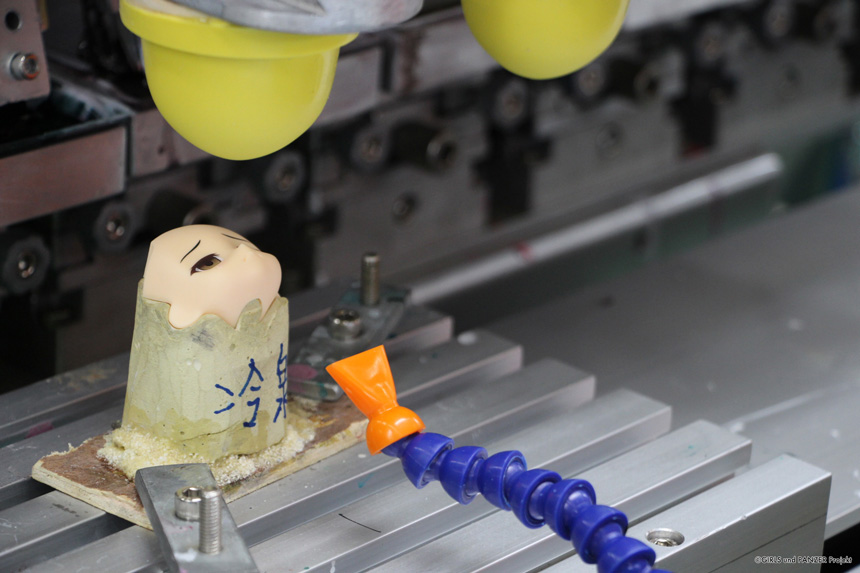

Next is printing. Patterns are poured into silicon pads, and by retransferring the patterns onto the parts, it is possible to make three-dimensional prints. Printing characters’ eyes is done within this process.

!=

Although it looks simple since machines do the printing, in order to make sure them get the perfect positions on where to print and how much curves they need to consider upon printing, numerous settings need to be done by human hands.

This is where the pad-printing machine prints eyebrows on Nendroids. In order to ensure all the products have the same facial expressions, cooperation between the employees and machines is crucial.

Finally, it comes to assembling, gluing, and packaging. It is where printed parts are put into one piece, and then packaged. The very important color-transfer preventing films are inserted within this process.

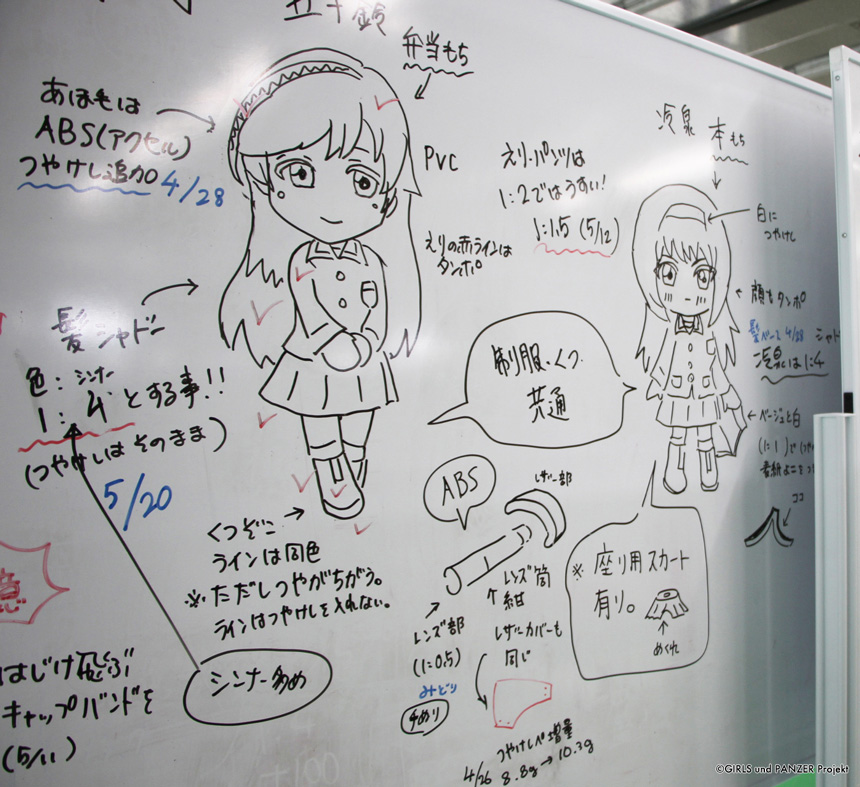

Within the factory, there are white boards with illustrations on them, inspirational graphic art on the wall, boasting Good Smile Company’s fun environment. David Choe, who is a good friend of the Good Smile Company’s president, Aki, drew the graphic art on the wall.

Figures go through these kind of various processes before they come into your hands. Of course, there are more where those come from such as the initial planning, designing the molding machines and so on. If you are interested in further information on the manufacturing process, please check out the special website which illustrates the whole process of figure making.

http://special.goodsmile.info/goodsmileworks/

Rakutsuki Factory not only produces authentic products “Made in Japan”, but also contributes to stable, sustainable work environment, and creating jobs for citizens of Kurayoshi-City. Also, we believe development of new production technologies is very important when it comes to making figures more freely without being limited by the existing technology. We are already taking few steps on it, such as making complete digital data of the molding process.

How would hiring the new factory manager affect the manufacturing process? Will it help us with our goal on innovating the world of figures? Stay tuned for more news on the Rakutsuki Factory!

Special interview about the project will be update soon! ...